11 Food Grinder and Dehydrator

A food pulveriser and Dehydrator system is used to reduce food waste volume by up to 90%, creating a disinfected, odorless and shelf stable product that can be taken to a composting facility to be fully Composted, or utilized as a soil amendment. Knowledge of Composting or composting basics is not required to operate these units.

Equipment and Materials

- Food Pulverizer and Dehydrator unit

- Collection Containers

- Cleaning supplies

- Larger units may require specialty electrical plug in’s. Setting up and Operating a Food Pulveriser and Dehydrator system

Each manufacturer will have a slightly different set up, so this is meant as a guide only, and manufacturers guidelines should be utilized.

Step 1 – Collection of Food Scraps

- Collection of food scraps will follow the same method as any other Composting system. Typically, all food scraps are acceptable in a Grinder/Dehydrator unit.

Step 2 – Loading the unit

- Unit is loaded daily with Food Scrap Material until an appropriate volume of material has accumulated.

Step 3 – Running the cycle

- The unit runs it cycle over a period of time. This can take between 8-24 hours to run a cycle.

Step 4 – Harvesting the material

- Material is harvested out of the unit.

Step 5 – Storage of material

- The material that is harvested is sterile and inert and therefore shelf stable and can be kept for a long period of time before use. Users of this system describe a slight earthy and/or coffee smell.

Note: A food Grinder and Dehydrator is not Composting, but it is reducing the weight and size and pest attractiveness of organic materials. This material can be applied directly onto land, however there are conflicting reports as to whether this is beneficial in the short term to soil and plants as the material will need to be further broken-down utilizing nutrients in the soil to complete this process. This material can also be transported to a composting facility at a lower cost (due to less water weight) to be fully composted and ready for application to Soil.

Bokashi Composting

System Set up

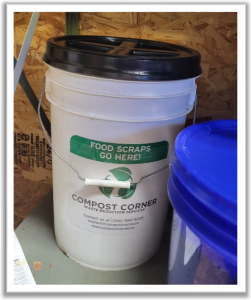

To set up a Bokashi Composting system three things are required. A container with an air tight seal Bokashi grains and food scraps. A 6 gallon bucket with a gamma seal lid and Bokashi from Lily Plain Gardens here in Prince Albert were utilized. The food scraps were obtained through the food scraps collected from the kitchen that were not utilized in the Vermicomposting system.

To set up Bokashi Composting food scraps are added along with Bokashi grains. For every one pound of food scraps added a handful of Bokashi grains is added. As the process is an anaerobic fermentation process the food scraps are pressed down so that there is no air space in the container. Once the container is full the lid is sealed, and it is left to ferment for 2 weeks.

Food Scraps are added to bucket and pressed down to avoid any air spaces. Bokashi Grains are added to food scraps

Bokashi Grains are added to food scraps

Bokashi Grains and food scraps are added in layers until the bucket is full

Material is left to sit for 14 days to ferment

After the fermentation process is completed the fermented food scraps can be utilized in the any type of Composting system as a high nitrogen addition to the Compost. It is beneficial to the Vermicomposting system as it optimizes food for the worms by predigesting the material.

After the fermentation process is completed the fermented food scraps can be utilized in the any type of Composting system as a high nitrogen addition to the Compost. It is beneficial to the Vermicomposting system as it optimizes food for the worms by predigesting the material.

A natural process that turns organic material into a nutrient-rich soil amendment. The process involves the decomposition of organic matter by microorganisms like bacteria, fungi, and other decomposers.

The leftover or discarded portions of food that are not consumed or used.

Substances derived from living organisms or once-living matter. These materials originate from plants, animals, microorganisms, and other living organisms.

Composting with red wiggler worms in a controlled and enclosed environment to produce a nutrient- rich compost called Vermicast.

Refers to a biological process or organism that occurs or thrives in the absence of oxygen.

A chemical element crucial for living organisms and plays essential roles in various biological processes, including composting. Nitrogen-rich materials, often referred to as "greens," include items like kitchen scraps, fresh plant material, and manure. Nitrogen is balanced with Carbon in the Composting process to transform the raw organic material into the stable humus product recognized as Compost.