2 System Selection Guidance

Any Composting system you choose must meet your needs. First determine what these needs are in order to pick the best system that fits your space, time and budget.

Assessment of Needs

In order to determine the best system for On site Composting we need to assess your needs and your unique situation.

- How much space do you have to dedicate to Composting?

- Do you have space indoors or outdoors?

- What kind of budget do you potentially have for Composting? Or another way of looking at this is “ how much does your current garbage pick up cost and how much could be saved if you diverted approximately 40% of the waste.(and 100% of the smelly stuff)

- What type of materials would you like to be Composting? i.e. Food Scraps, vegetable waste, meat waste, pre- consumer waste (from the kitchen) post consumer waste (from the waste collection bins)

- How much material do you have to Compost? Is it a small coffee room, restaurant, Cafeteria, kitchen?

- Do you have animal issues on site? I.e. animals getting into garbage containers?

- Would you have a use for the end product?

- Compost Sales

- Landscape Use (Use around trees or lawn) (Give away to community members, or staff)

- Vegetable Garden Use (Give away to community members or staff)

- How much of a concern is the “ick” factor? Do you feel like staff might be squeamish about dealing with food scraps?

- How much time do you have to dedicate to a Compost system

Compost tables

| System Comparison Table | Vermicompost | In-Vessel barrel system | Backyard Compost pile | Windrow | Aerated Static Pile | Food Dehydrator |

|---|---|---|---|---|---|---|

| Space | ||||||

| How much space do you have to dedicate to Composting? | ||||||

| Under 1 m2 | x | x | ||||

| 2m2 – 10m2 | x | x | x | x | ||

| 10m2 – 100m2 | x | x | x | x | x | |

| 100m2+ | x | x | x | x | ||

| Indoors or Outdoors | ||||||

| Indoors | x | x | x | |||

| Outdoors | x | x | x | x | ||

| Costs | ||||||

| (Those with multiple costs are dependent on Volume) | ||||||

| Under $100 | x | x | ||||

| $101-$1000 | x | |||||

| $1001 – $10,000 | x | x | ||||

| $10,000 – $40,000 | x | x1 | x | x | ||

| $40,000 + | x | x1 | x | x | ||

| Types of Feedstock | ||||||

| Food Scraps (Just vegetable Matter) | x | x2 | x | x | x | x |

| Food Scraps including Meats | x2 | x | x | x | ||

| Cardboard | x | x2 | x | x | x | |

| Sawdust | x | x2 | x | x | ||

| Wood chips | x2 | x | x | |||

| Fish Entrails | x2 | x | x | x | ||

| Compostable Plastics | x2 | x3 | x3 | x | x | |

| Volume | ||||||

| How much material do you have? | ||||||

| Less than 1kg/day | x | x2 | x | x | ||

| 1 – 10kg/day | x | x2 | x | x | x | |

| 10kg – 50kg/day | x | x2 | x | x | x | |

| More than 50kg/day | x | x2 | x | x | x | |

| Potential End product use | ||||||

| Sales | x | x5 | x5 | x5 | x | |

| Landscape Use (Use around non-edible trees or lawn) | x | x | x | x | x | x |

| Vegetable Garden Use (edible trees or lawn) |

x | x6 | x6 | x6 | x6 | x |

| 1 Equipment needed to turn pile. If you already have a loader or skid steer the costs can be significantly less | ||||||

| 2Depends on the In-Vessel system utilized | ||||||

| 3 Must be certified Home Compostable | ||||||

| 5 Must meet CFIA Requirements under the Fertilzer Act | ||||||

| 6 If using High Risk Feed stocks such as meat, diseased plant materials, or weeds ensure there is a heating phase to eliminate pathogens and weed seeds before using on vegetable gardens | ||||||

This table assists in making decisions about the right type of system to use.

Overview of Each Composting System

After assessing your needs, you may find that one or two systems will work for you. Further information below will provide more context and information to help aid in your decision.

Vermicomposting

The process of turning organic waste into a soil amendment using red wiggler worms. The worms will eat rotting material and produce castings that are a highly sought after gardening amendment.

Scale

- Small scale – for smaller kitchens, one bin can be placed in a cupboard or closet. One standard 10 or 20 gallon Plastic tub with an adequate number of worms can process up to 0.5kg of waste per day.

- Larger Scale – for Commercial kitchens a number of bins or flow through systems can be set up to process large amounts of organic material. With enough worms, the system is only limited by the physical space that you have to place them in.

- During our project Saskatchewan Polytechnic was able to process an average of 1kg of material a day in a heated shed approximately 48 sq ft with 9 bins. This feed rate increased over the project and with some time the worms could easily divert 100% of the waste from the kitchen.

- The project can expand within this space as there is shelf space for up 30 plastic bins. Worms reproduce rapidly, so the worm population and feed rate can increase with the same amount of space.

Feed Stocks

- Vegetable or plant matter Vermicomposting systems are best when set up to process vegetable or plant matter only.

- Meat, dairy, compostable plastics are not typically processed in a Vermicompost system due to the time (and sometimes smells) that can be produced when processing these items. However, when these items are pre-processed in a Bokashi composting system or the system is large enough they may be added to the Vermicomposting system.

Location and Space

- Indoors Only or summer operation only – The limiting factor here in Saskatchewan or Canada, is that the optimal temperature range is between 15 degrees Celsius to 30 degrees Celsius. Therefore, they need to be kept inside a climate-controlled building.

Work involved

- Vermicomposting requires regular maintenance or care. The Red wiggler worms can be treated as Livestock and routine checks, routine feedings in small and consistent amounts, monitoring and correcting for worm health are needed to keep the worms healthy and happily eating food scraps. Regular monitoring will also allow you to get ahead of problems before they arise, or before they become a larger problem.

End Use

- The Vermicast product can be utilized on houseplants, flower and vegetable gardens etc… Vermicomposting does not have a heating phase, so if the feed stock has any potential pathogens or weed seeds these will not be removed in the Composting process. With vegetable food scraps this is not typically a concern, however you will find a lot of volunteer squash, tomatoes, peppers and other seeds volunteering from the end product.

Drawbacks

- As die-off’s can happen unexpectedly a back up systems should be in place to deal with food waste.

- Staff involved will have to come in contact with a large amount of writhing wriggling worms. This can be an “ick” for some people.

- As they require an indoor space in a Canadian Winter. Space available will be the limiting factor when determining volume.

A Vermicomposting system can process material quickly and provide a product that will be sought after by gardeners, houseplant enthusiasts and landscapers alike.

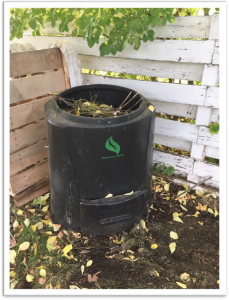

In-Vessel Barrel System

In-vessel composting generally describes a group of methods that confine the composting materials within a building, container, or vessel. An In-vessel barrel system is an enclosed system that mixes, and turns and may add water and/or heat to the material in order to control the Composting process. Please note that this observation is from our use of the BrewNature In Vessel Composting System. Other systems will vary in their scale, feed stocks, location, space and end use.

In-vessel composting generally describes a group of methods that confine the composting materials within a building, container, or vessel. An In-vessel barrel system is an enclosed system that mixes, and turns and may add water and/or heat to the material in order to control the Composting process. Please note that this observation is from our use of the BrewNature In Vessel Composting System. Other systems will vary in their scale, feed stocks, location, space and end use.

Scale

- Larger Scale – Due to factors such as cost and processing speed and the size required in order to create the heating phase these units are typically reserved for larger commercial operations that produce over 15kg per day of food waste. Most systems can be sized according to need.

Feed Stocks

- This will be dictated by the system utilized, however In Vessel Barrel systems do usually take all types of food scraps as they will have a thermophilic (heating) phase as part of the Composting process. Some In Vessel systems specialize in handling odorous or harder to Compost materials.

Location and Space

- Will vary depending on the unit purchased. But they can typically be utilized in both indoor and outdoor settings with some protection from weather in outdoor settings

- Require outdoor space for the finished product to Cure for 30 days before it is ready for use and for storage until the product is utilized. This is piled outdoors, and the space will depend on the volume of finished product produced each month.

Work Involved

- Typically, the work involved with an In Vessel system is to load and unload the unit and monitor the process to ensure all processes are working correctly. Loading and unloading time will be dependent on volume and maintenance and monitoring will be dependent on the unit.

End Use

- As In vessel system typically ensure a thermophilic or heating phase they can meet requirements for pathogen and weed seed inactivation and therefore can most likely be utilized for most applications after the Compost has cured and is considered Mature and stable.

Drawbacks

- This will be dependent on the in-vessel system utilized. Do your own research from other users with similar feedstocks to get their feedback.

An In-vessel system is great for processing food scraps quickly and out of site and are less susceptible to outdoor conditions and attracting pests. They do typically require a larger financial investment which can be offset in a reduction of hauling costs. As they are a mechanical system they can breakdown and not only require composting maintenance but also maintenance of the specialized equipment itself.

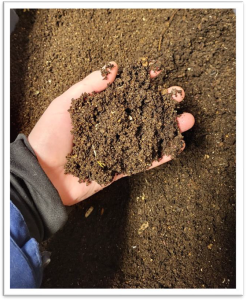

Backyard Compost Pile

A Backyard Compost pile is a pile of organic material, that includes food scraps and leaves, straw or woody material. This can be processed in a manufactured or home-made Compost Bin to keep it neat. A backyard pile will need to be turned with a Compost spinner or Pitchfork occasionally.

Scale

- A Backyard pile is suitable for a typical family kitchen up to 4 to 5 kg/week.

Feed Stocks

- Vegetable and plant matter can be composted in a backyard pile. Meats, and dairy are discouraged as they can attract pests.

Location and Space

- A backyard pile typically needs at least 3 square meters of ground space outdoors. This will allow for a pile that scraps are added to, an active composting pile and a curing pile.

Work involved

- Turning the pile utilizing a pitchfork, shovel or compost turner, to incorporate air occasionally, adding to the pile, and distributing the finished compost is the physical labour involved in a Backyard pile.

End Use

- Backyard Compost is utilized within the landscaping or garden in the adjacent area. Backyard Compost piles are not typically suitable for saleable compost.

Drawbacks

- A backyard compost pile is a small system that can handle a small amount of kitchen waste, but it can be quite labour intensive as more volume is added.

A Backyard Compost pile can be an easy and efficient way to deal with a small amount of kitchen waste when access to outdoor space is available and someone is willing to maintain and monitor the Compost system.

Windrow

Windrow

Windrow compost systems are a larger pile or row of organic material that includes the food scraps, leaves, or straw, or woody type materials that are turned with the use of a loader, skid steer, or Compost turner.

Scale

- A windrow compost system is infinitely scalable with space and equipment.

Feed Stocks

- Any organic material can be composted using a windrow system. Compostable Plastics, and papers can pose a concern if they are blown out of the pile as it is an outdoor and open system. This can create an unsightly mess of material blowing about the site.

Location and Space

- Windrow systems take up a lot of outdoor space as they require space for receiving materials, mixing, active composting, turning area, and maturing area. Considerations such as run off, drainage and proximity to other land uses is a consideration.

Work involved

- Windrows are maintained by monitoring temperature, and moisture levels daily and turning the piles to aerate and mix the material. As this method is typically used for large quantities of material there can be a lot of work involved.

- Standard loaders and skid steers can be utilized to turn Compost piles or specialized Compost turners can be utilized to save on space and time.

End Use

- A properly managed windrow that has reached its appropriate thermophilic (heating phase) is appropriate for all end uses. This includes the sale of Compost when CFIA labelling requirements are met.

Drawbacks

- The space required to have a well functioning is windrow composting system is typically the limiting factor. Space for storage of feed stocks, storage of Finished and maturing piles and of course an active composting area.

- The storage of raw feed stocks can also be an issue as raw feed stocks can be attractant to pests. If there is not enough material to create a windrow each day, the raw feedstocks will need to be stored for an amount of time until they can be incorporated into an actively composting windrow. Raw food scraps must be covered in order to prevent pests and wildlife from being attracted to the material.

- As this is done in an outdoor environment wind can be a concern as it will blow lighter material around the space, which can look messy and is difficult to control.

Aerated Static Pile

Aerated static pile (ASP) composting refers to any of a number of systems used to biodegrade any organic material without physical manipulation during primary composting. The blended admixture is usually placed on perforated piping, providing air circulation for controlled aeration.

Scale

- Aerated static pile systems are typically utilized to handle large amounts of feed stocks.

Feed Stocks

- When mixed correctly aerated static pile can handle any type of organic material.

Location and Space

- Aerated static pile systems are take up a large footprint outside and require a specially built facility.

Work involved

- Aerated Static Piles do not need regular turning as the name implies. The work involved is mixing, loading the bays monitoring for temperature and moisture daily and then harvesting and moving to curing piles once the process has completed.

End Use

- A properly managed aerated static pile that has reached it’s appropriate thermophillic (heating phase) is appropriate for all end uses. This includes the sale of Compost when CFIA labelling requirements are met.

Drawbacks

- Air blowers can get clogged on an aerated static pile system which reduces it’s efficiency and use.

- These systems can be expensive to set up and maintain.

Dehydrators

Food Pulverisers and Dehydrators pulverize and dehydrate food scraps into a shelf stable, inert product that can be further Composted, or added to land as a soil amendment. We reached out to Selkirk College in British Columbia to get information on their experience with the dehydrator and pulveriser.

Scale

- Food Scrap Dehydrators can come in many different scales. There are companies that make both home scale and commercial kitchen scale equipment.

Feed Stocks

- Any organic material including compostable plastics, meat, dairy.

Location and Space

- These are typically installed indoors and can be a small enough for a typical household kitchen, or large enough to handle large commercial kitchens. The size will vary depending on manufacturer and volume requirements.

Work involved

- The work involved with a dehydration unit are to load and unload the unit, cleaning collection bins, and distributing the end product. The unit will dehydrate and pulverize the food scraps so that they can be easier to transport.

End Use

- Dehydrated and pulverized food scraps are not necessarily recommended for direct use in gardens or soils. The inert material will need to break down further in order to release nutrients into the soil. When this material breaks down in the soil it will utilize nitrogen available in the soil to complete this process, leaving less nitrogen available for plants. The dehydrated and pulverized material could be shipped to the closest composting facility for further processing before being added to the soil. However, dehydrating the material will reduce the material weight significantly and will reduce hauling costs.

Drawbacks

- The end product requires further breakdown and this will either happen in a compost pile, or in the soil where it has the potential to steal nitrogen from the plants that you would like to grow.

- These units can be very expensive.

Note: For any Composting method chosen, it is recommended that you seek out someone with experience in the Composting Method of your choice to help you to set up your Composting Program. This Toolkit is meant to be a guide only and does not replace experience or knowledge.

A natural process that turns organic material into a nutrient-rich soil amendment. The process involves the decomposition of organic matter by microorganisms like bacteria, fungi, and other decomposers.

The practice of composting organic materials directly at the location where the waste is generated. Instead of transporting organic waste to an off-site facility or landfill, on-site composting involves creating a composting system within the premises of a residence, business, farm, or institution.

The leftover or discarded portions of food that are not consumed or used.

Organic materials are mixed and placed in bays over perforated pipes typically attached to blowers to keep piles aerated without physical manipulation of the Compost Pile.

In the context of composting, a windrow refers to a long, narrow pile or row of composting materials strategically arranged to facilitate the decomposition process. Windrows are typically formed outdoors and are commonly used in large-scale composting operations.

Any biodegradable waste material that originates from living organisms or contains organic compounds. This category of waste includes materials that can decompose naturally through the action of microorganisms. Organic waste can be both plant-based and animal-based.

Substances derived from living organisms or once-living matter. These materials originate from plants, animals, microorganisms, and other living organisms.

Composting with red wiggler worms in a controlled and enclosed environment to produce a nutrient- rich compost called Vermicast.

A type of material derived from renewable resources or biodegradable polymers that, under specific conditions, can break down into environmentally benign components through composting processes. Not all composting processes will break down compostable plastics.

Nutrient-rich organic material produced through the process of vermicomposting, also known as worm castings or worm poop.

An advanced composting method that takes place within a closed container or vessel, providing a controlled and accelerated environment for the decomposition of organic materials. This approach is particularly suitable for large-scale composting operations.

A chemical element crucial for living organisms and plays essential roles in various biological processes, including composting. Nitrogen-rich materials, often referred to as "greens," include items like kitchen scraps, fresh plant material, and manure. Nitrogen is balanced with Carbon in the Composting process to transform the raw organic material into the stable humus product recognized as Compost.